-

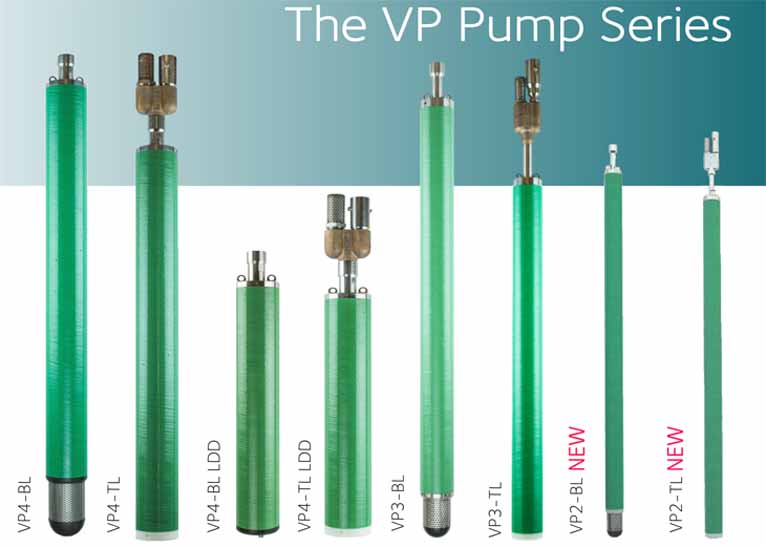

Landfill Leachate, and Remediation Pumps: - Fully Automatic, Float Actuated Pumps The Viridian range of pumps (VP Pumps) are designed specifically for pumping landfill leachate, landfill gas condensate and contaminated groundwater. As no down-well level control device is required, the VP pumps lend themselves to being part of a multi-well pumping system. This makes overall system control very simple. With minimal training, the site personnel quickly become confident with both pump and system. Available in a range of sizes and variations, and capable of discharging up to 1.1 litres of liquid per cycle. The bottom-filling versions are specifically designed for the harsh conditions of pumping landfill leachate. Available as a top loading version, for groundwater remediation applications, as well as a short version, and the 'LDD' (low drawdown) when minimum liquid head is vital. The VP2 and VP3 range has a reduced discharge capacity but it is ideal for smaller borehole sizes. As the VP pumps are driven by compressed air, a multi-well system would have an air-main connecting each pump - a far safer power source than electricity cables and less costly. VP Pumps also do not require an external form of control. Pulse Counters, for volume and flow rate measurement also available. Download Brochure

-

Bioremediation Products Fieldtech Solutions is proud to represent EOS Remediation in Australia. EOS Remediation is the leading provider of bioremediation products that re-engineer the groundwater environment, transforming contaminants into non-toxic end products. EOS Remediation’s products are ecologically sustainable (USDA Certified BioPreferred Products), and cost-effective with proven results. Most of these products are being manufactured locally here in Australia. Their diverse family of products, driven by extensive research and development, are available to meet a variety of project needs. If you have a current bioremediation project, and you are you looking to calculate the volume of EOS product required, we request that you please fill in the Site Evalution Form and email back to us so we can help. Not all fields may be known but please fill in as much information as you can. Download Site Evaluation Form

-

These convenient socks pre-filled with approximately 312.5 g of EOx® Powder. They are 38mm diameter, suitable for 50mm wells or larger. EOx® is a granular powder of calcium peroxide that provides slow and steady oxygen release for long-term aerobic biodegradation. Suitable for enhanced aerobic biodegradation of BTEX, PAHs, DRO, MTBE, VC and other complex contaminants in soil and groundwater.

-

Passive skimmers for fuel removal The KV Passive Skimmers utilize a patented membrane material to separate fuel from water. Subsurface fuel spills are recovered by membrane separation so the fuel simply falls into the passive "bailer" reservoir. These fuel bailers easily recover LNAPL such as petrol and diesel from groundwater.

KV50 and KV100 Dimensions

-

LNAPL Skimming Socks for 50mm Monitoring Wells The easiest way to remove small amounts of fuels from monitoring wells is with these low-cost skimming socks. Each sock holds about 500ml.

-

Designed for applications such as Aquifer Injection, Groundwater Monitoring, Methane gas control or collection (typical in landfills and mines), Vacuum sampling at or below Leachate pads, Formation pressure monitoring, and Vadose zone sampling and injection. The Environmental Packer is a Fixed-End Style Packer manufactured using either Neoprene, EPDM or Viton® rubber gland element and Type 304 or Type 316 stainless steel.Applications:

- Remediation / Groundwater Injection

- Groundwater monitoring

- Methane gas control or collection in landfills and/or mines

- Monitoring formation pressures

- Vacuum sampling under leachate pads

- Vadose zone sampling and injection

-

This all pneumatic box will shut off the air supply to down-hole pumps when the tank, drum or IBC becomes full. This prevents overfilling of the drum and creating a spill. Ideal for LNAPL recovery projects. Comprising of a separate control box and tank sensor, the control box can be mounted separately from the drum. The tank sensor is screwed into the drum and connected to the control box by a small air hose. Being all pneumatic makes this inherently intrinsically safe.

We ship all our products with recycable and biodegradable materials.

We ship all our products with recyclable and landfill-biodegradable materials.

We use newspaper as filler and recycled cardboard boxes where possible to replace non-recyclable material.