Plug & Play Compatability – Smart Sensors

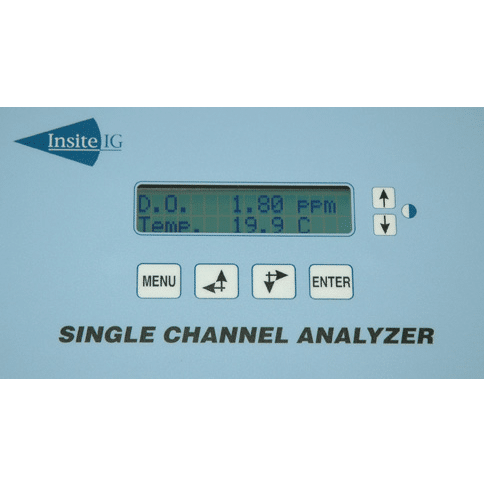

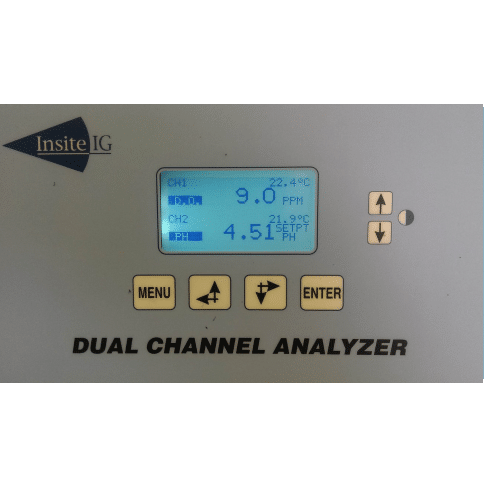

The InsiteIG Single Channel Analyser is a unique system that combines advanced electronics with solid-state, smart sensors. The analyser will accept any standard InsiteIG DO, SS, pH, or ORP sensor and automatically configures for the correct operation. The system allows for flexible and economical process monitoring and control.

Fluorescence Dissolved Oxygen —Theory of operation

A very specific energy wavelength is transmitted to a ruthenium compound immobilized in a sol-gel matrix. The ruthenium will absorb this energy, changing the outer electron’s energy level. The electron will then collapse back to its original energy state, emitting the energy as a photon with a different specific wavelength. This is called fluorescing. If the intensity of the transmitted wavelength is tightly controlled, the amount of fluorescing is both predictable and repeatable. If oxygen molecules are present the amount of fluorescing is reduced, referred to as fluorescence quenching. By measuring the amount of quenching it is possible to determine the amount of oxygen present.