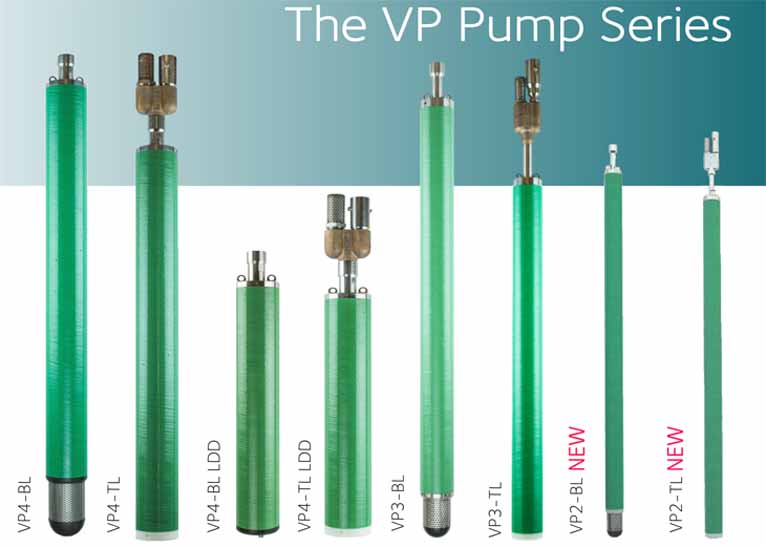

Landfill Leachate, and Remediation Pumps: – Fully Automatic, Float Actuated Pumps

The Viridian range of pumps (VP Pumps) are designed specifically for pumping landfill leachate, landfill gas condensate and contaminated groundwater. As no down-well level control device is required, the VP pumps lend themselves to being part of a multi-well pumping system. This makes overall system control very simple. With minimal training, the site personnel quickly become confident with both pump and system.

Available in a range of sizes and variations, and capable of discharging up to 1.1 litres of liquid per cycle. The bottom-filling versions are specifically designed for the harsh conditions of pumping landfill leachate.

Available as a top loading version, for groundwater remediation applications, as well as a short version, and the ‘LDD’ (low drawdown) when minimum liquid head is vital. The VP2 and VP3 range has a reduced discharge capacity but it is ideal for smaller borehole sizes.

As the VP pumps are driven by compressed air, a multi-well system would have an air-main connecting each pump – a far safer power source than electricity cables and less costly. VP Pumps also do not require an external form of control.

Pulse Counters, for volume and flow rate measurement also available.