-

Trim your casing below ground level safely and easily These new internal pipe cutters have an ingenious design to ensure a safe, easy, and clean cut without any PVC shavings falling into your monitoring well. The IPC50 and IPC100 are an ingenious design of internal pipe cutter. It uses a replaceable cutting wheel blade to give a clean cut without any shavings. As you tighten the handle and rotate, the cutting wheel pushes against the inside of the casing and cutting cleanly through. The replaceable cutting wheel pushes against the casing from the inside out, and is tightened with each rotation to give a clean and precise cut. Available in sizes to suit 50mm and 100mm casing.

-

Screen and Casing Bore Pipe for Monitoring Well Installations Cut your costs for well installation and operate more sustainably on site. Each pair of 3m lengths of pipe is sleeved in biodegradable plastic, which means the sleeve will biodegrade away when disposed to a landfill, allowing you to help reduce the amount of plastic waste build-up. Most environmental screen and casing is wrapped in conventional plastic but this is adding to our plastic waste problem. The FieldTech Solutions Wellscreen is wrapped in biodegradable plastic preventing further plastic waste. We also use biodegradable packing tape in our shipments. 50mm casing and screen is made from uPVC and to class 18 size and is manufactured following the Australian Standard for Monitoring Wells. Each piece has a coarse male/female thread for easy field assembly and is o’ring sealed. Our biodegradable plastic wrapping:

- Will only biodegrade once in a microbe rich environment such as a landfill

- Does not require high oxygen or temperature to biodegrade such as in a commercial compost

- Helps you to operate more sustainably

-

SD400 - A Large Well Cover for Remediation The SD400 Cover is designed mainly for remediation work where bulky equipment may need to be around the well head. This large cover with a hinged lid offers wide access, with an easy lid opening. It can be ordered with or without a sheet metal skirt fitted.

- 600mm diameter opening

- 850mm overall diameter

- All ductile iron cast construction with sheet metal skirt (500mm long)

- Hinged lid requires only 1 key to lift up

- Designed to be cemented into the ground flush

- Class D400 load rating, (40 ton load)

-

CETCO Bentonite, Gels, and Cement We now stock bags of bentonite, making it easier to get all your well installation material from the one location. 25kg Bags of bentonite are available in granules or chips. Bentonite tablets and coated slow release tablets are also available for applications where immediate reaction with water is not desired.

-

A Class E Rated Cover for 100mm Wells The Nondo200 contains high quality machine cast iron lid and base, with a strong plastic skirt. It is ideal for 100mm monitoring wells and has been tested to exceed load bearing requirements for traffic suitability for Australian Standard AS3996 Class E, which is typically for heavy duty applications. The large 250mm OD, 200mm ID (164mm between bolt holes) makes the Nondo200 ideal for remediation wells, or in situations where a 'GasClam' sensor is to be installed.

-

The Nondo Mini monitoring well cover is our budget bolt-down, flush mounted well cover. It is designed to be used for monitoring wells or for soil vapour installations. With the bolts outside the inner working space, the Nondo Mini gives you maximum internal room for such a small cover. Features:

- 2 counter-sunk flush bolts to reduce the risk of trip hazards, as there are no protruding bolt heads

- High strength cast iron in black epoxy

- White powder coated lid

- Large internal opening of 124mm (98mm Bolt head clearance)

- Small 150mm outside diameter

- Ideal for standard 50mm monitoring wells or soil vapour implants

-

A Class E Rated Cover for Heavy Duty Applications The Nondo CE180 monitoring well cover is an all cast iron, 'Class E' rated well cover, designed for extra heavy duty applications. It is ideal for 50mm monitoring wells and has been tested to exceed load bearing requirements for traffic suitability for Australian Standard AS3996 Class D & Class E. The small 180mm OD makes it ideal for drillers who typically use a 200mm concrete corer. The CE180 has two new concepts for groundwater monitoring well covers:

- A special shaped skirt to allow a wider concrete support lip and with a larger opening than comparable covers of similar diameter (116mm opening)

- Bottom sealed bolt holes with removable grub screws for easy bolt hole cleaning if necessary. This ensures ultimate sealing from surface water ingress

-

A medium sized well cover with some big features The Nondo180 monitoring well cover contains a high quality machined cast iron lid and base, with a strong plastic skirt. It is ideal for 50mm monitoring wells and has been tested to exceed load bearing requirements for traffic suitability for Australian Standard AS3996 Class D. The small 180mm OD makes it ideal for drillers who typically use a 200mm concrete corer.

-

A New Concept for Standpipe Covers - Hidden Hinge Design The 100mm square yellow steel standpipe cover has a unique hidden hinge design which provides a rain proof cover. Traditional looking standpipe covers have hinges which are exposed to the elements and therefore prone to corrosion and eventually seizing up or dropping off. The unique design has addressed this weakness. These low-cost covers have a bright yellow powder coated finish, and are also available as galvanised.

-

A better designed well cover using recycled plastic for sustainability The Nondo Eco 180 well cover is designed with sustainability in mind. The reuse of current resources and the conservation of our future resources are fundamental to all our design concepts where practical. The Nondo Eco 180 is made entirely from recycled plastic and has been tested to meet load bearing requirements for traffic suitability for Australian Standard AS3996 Class D.

- One piece gasket seals both the lid and around bolt holes heads to prevent surface water ingress, and completely seals the well

- 2 stainless steel bolts, counter sunk with 8mm hex for secure lid clamp down

- 180mm diameter OD, large 146mm ID, 122mm between bolt holes

- High strength recycled plastic (HDPE & Delrin) is resistant to petroleum products

- Unlike steel, recycled plastic will never rust

- Lower cost than traditional cast iron covers

- Light weight only 1.2kg but rated for heavy trucks

- Load tested to AS3996 Class D traffic rating

- Ideal for 50mm monitoring wells

- The all recycled plastic Eco180 will never rust leaving your installation work always looking good

- No more finger crushing under heavy lids, the Eco180 lid is lightweight with no sharp edges

-

Made from post-consumer recycled plastic (i.e. bottles and other plastic waste sent for recycling), these stylish upright covers give your monitoring well a professional finish. By purchasing products made from recycled plastic you are supporting the plastic recycling industry. The reuse of current resources and the conservation of our future resources are fundamental to all our design concepts where practical. The Heavy Duty Standpipe Cover range is thick walled (23mm) HDPE (high density polyethylene) to give you a very strong, chemically inert and petroleum resistant well cover. They are available in blue or black with large bright orange reflectors for high visibility.

-

Passive skimmers for fuel removal The KV Passive Skimmers utilize a patented membrane material to separate fuel from water. Subsurface fuel spills are recovered by membrane separation so the fuel simply falls into the passive "bailer" reservoir. These fuel bailers easily recover LNAPL such as petrol and diesel from groundwater.

KV50 and KV100 Dimensions

-

Discoverer Core Sample Trays Made in Australia, the Discoverer® core trays are rugged and lightweight. They are now available in black recycled plastic too and are also fully recyclable. Safety: The Discoverer® plastic core trays remain relatively cool to touch when left outside, unlike metal trays. Therefore no more painful burns when handling core trays. Rounded edges mean no more dangerous sharp edges, leading to improved safety when handling. Built in Handles on both ends of the trays provide safe and easy use when handling. Being manufactured with a one piece mold means no unusable trays in use, reducing the chance of workplace related injuries. Superior Strength and Durability: Made from a one piece mold, meaning no pop rivets and welds which increases the products strength and importantly no sharp edges. The Discoverer® is made using the highest UV stabilized polypropylene available making it exceptionally durable in any harsh mining or exploration environment. Manufactured from exceptional quality raw materials, which makes it extremely resistant to impact and crushing. The Discoverer® Sub Zero is manufactured for use in freezing conditions and trays are tested to minus 50°C. Ease of use: A bold start indicator has been designed to make it absolutely clear to the driller at which end they should commence loading the core from, eliminating possible errors in the logging process. The trays are colour coded, allowing for quick and easy identification of the different sizes both in storage and out in the field and when re-ordering. The Discoverer® has a built in ID Tag area and optional aluminum tag inserts providing a permanent record of contents. The Discoverer® has standardized sizing. The majority of sizes used in the environmental, mining and exploration industries are H, N, P & B core diameters. Lengths are standardised making all the trays 1m (3.49ft) long. Maintain Your Core Integrity: The materials used during manufacturing have a high level of resistance to organic chemicals that are found in some drill core recovery, meaning your core won’t become contaminated. The Discoverer® is non-magnetic and will not corrode keeping your core free from magnetic susceptibility when testing and ensures no corrosion of the trays occur. The unique raised ribbed design helps to retain the quality of your core by improving drainage. The Discoverer® core trays cannot be affected by insect infestations like wooden core boxes as the plastic is not penetrable. The plastic used in the core boxes will not migrate or leach into your core samples. The Discoverer® core trays have a range of accessories available and one of these is the custom made lid which assists to maintain your core’s integrity at all times. Only the Discoverer® core trays have unique a stacking capability, which allows the trays to stack perfectly on top of each other, loaded with core without touching the tray below. This means that your core is stored without interference, helping to retain the quality of the core.

-

Low-Flow Sampling has been the preferred method of choice for many years now in Australia for groundwater sampling. Now you can use disposable bladders responsibly by choosing our landfill biodegradable bladders. Fieldtech Solutions has developed landfill-biodegradable concertina style bladders, and also tube style bladders for 2 of the most popular low-flow groundwater sampling pumps. These bladders have the same biodegradable additive as our other disposable sampling products so that they will biodegrade once disposed to a landfill. *Concertina style bladders now also available in HDPE*

-

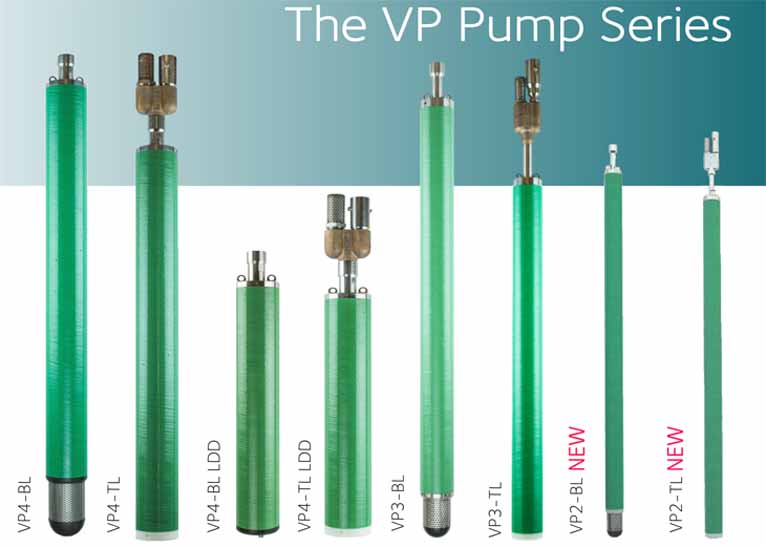

Landfill Leachate, and Remediation Pumps: - Fully Automatic, Float Actuated Pumps The Viridian range of pumps (VP Pumps) are designed specifically for pumping landfill leachate, landfill gas condensate and contaminated groundwater. As no down-well level control device is required, the VP pumps lend themselves to being part of a multi-well pumping system. This makes overall system control very simple. With minimal training, the site personnel quickly become confident with both pump and system. Available in a range of sizes and variations, and capable of discharging up to 1.1 litres of liquid per cycle. The bottom-filling versions are specifically designed for the harsh conditions of pumping landfill leachate. Available as a top loading version, for groundwater remediation applications, as well as a short version, and the 'LDD' (low drawdown) when minimum liquid head is vital. The VP2 and VP3 range has a reduced discharge capacity but it is ideal for smaller borehole sizes. As the VP pumps are driven by compressed air, a multi-well system would have an air-main connecting each pump - a far safer power source than electricity cables and less costly. VP Pumps also do not require an external form of control. Pulse Counters, for volume and flow rate measurement also available. Download Brochure